Technical

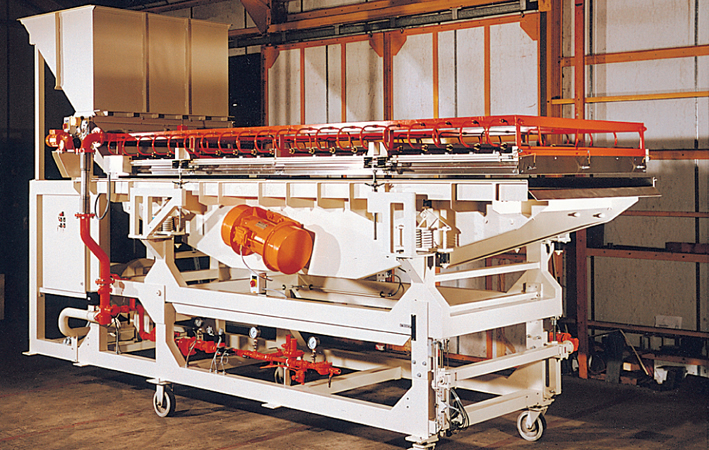

The Infra Red Micronizer is a fully automated continuous system which runs either as a stand alone plant or as part of a complete line 24 hours a day 7 days a week.

The Micronizing System is designed to be a fail safe, low maintenance cooking process. When running on a daily basis (8 hours per day), the only operator involvement at the Micronizer is for start up.

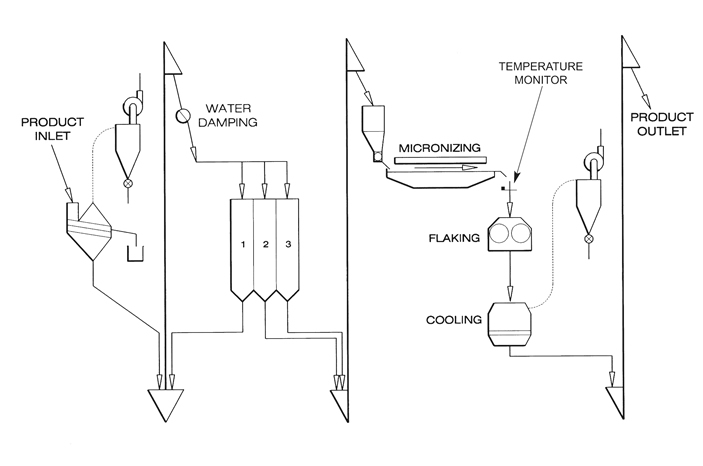

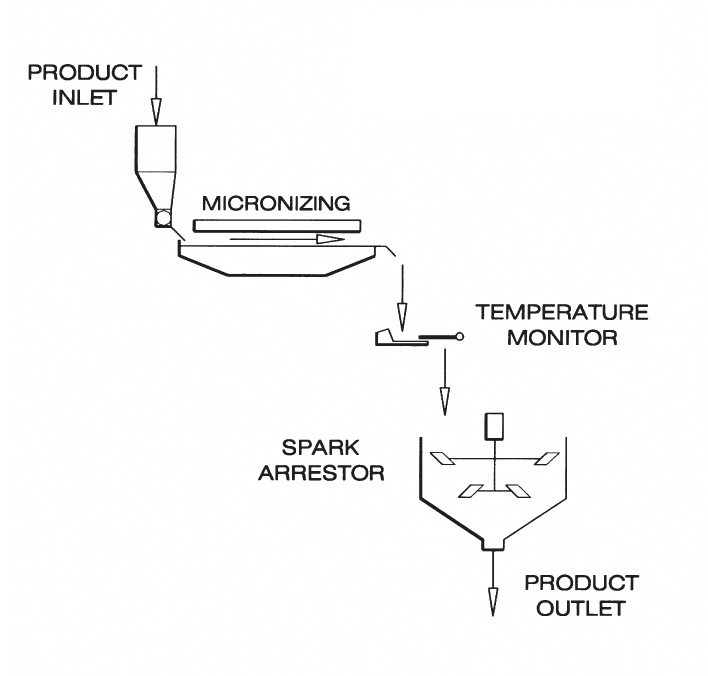

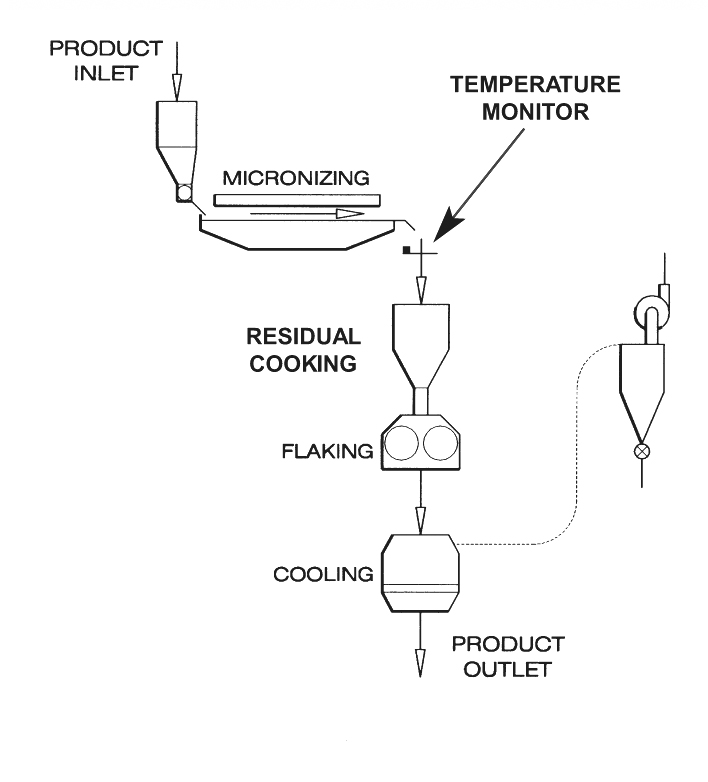

Process Flow

- Cleaning and aspiration of raw materials.

- Variable percentage water addition* to raw materials as required.

- Tempering period for proper water absorption

- Prepared raw materials supplied to the Micronizer via a hopper and variable speed feeder.

- Process parameters and temperatures are PLC or manually controlled and adjusted accordingly

- Gas controls, air pressures, fuel flow, material availability, infrared failure, motor rotations are all constantly monitored as fail safe “limits” by the ignition controller system

- Cooked Micronized materials fall directly into a heavy-duty flaking mill, residual cooking vessel or winnower, depending on the application. Hydraulics control “open and close” roll gap function automatically.

- Cooked Micronized products are cooled in a counter flow cooler to ambient +5 degrees C.

*Please use our contact form to request information on (Vibronet) water addition

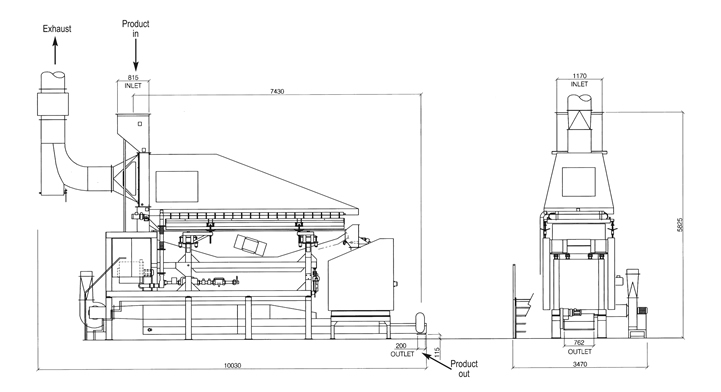

Foundation

Micronizing equipment should be installed on a suitable industrial quality floor, level, square and true, and attached to the ground via pre drilled holes in the mounting legs. Adequate ventilation should be provided.

Capacities

Capacities vary from 500 – 8000 kg/hr depending on the product and process parameters.

Cocoa capacities are up to 8 tonnes per hour.

Energy source: Natural gas or LPG Propane.

Typical energy consumption 0.082 kW per kg.

MR Series Vibratory table

| Model | Length | Burners | HRS |

|---|

| MR10 | 3m | 18 | • |

| MR10 | 5m | 30 | • |

| MR20 | 3m | 36 | • |

| MR20 | 5m | 60 | • |

| MR30 | 3m | 72 | • |

| MR30 | 5m | 90 | • |

MB Series Belt

| Model | Length | Burners | HRS |

|---|

| MB200 | 3m | 18 | • |

| MB200 | 5m | 30 | • |

| MB400 | 3m | 36 | • |

| MB400 | 5m | 60 | • |

| MB600 | 3m | 72 | • |

| MB600 | 5m | 90 | • |

Diagrams for the cereal, cocoa, soya and animal feed micronizing process can be viewed here.