The Process

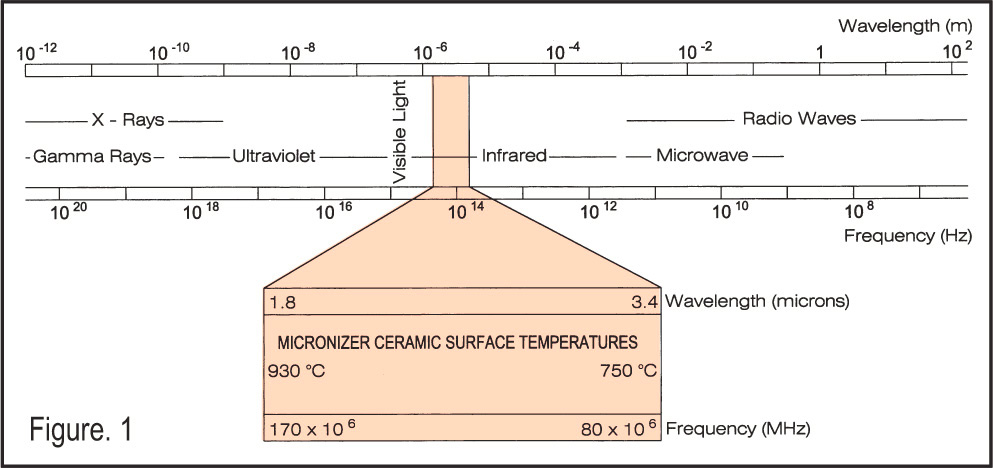

Infra Red Micronizing is a patented, dry thermal process. Infra red energy was discovered in 1800 by Herschel and the Micronizing process is concerned with infra red wavelengths of 1,8 – 3,4 microns (Micronizing Company’s name was derived from this unit of measurement which describes the infra red wavelength)

Infra Red Micronizing is a patented, dry thermal process. Infra red energy was discovered in 1800 by Herschel and the Micronizing process is concerned with infra red wavelengths of 1,8 – 3,4 microns (Micronizing Company’s name was derived from this unit of measurement which describes the infra red wavelength)

The Micronizing process must not be confused with microwave cookers, which use a higher wavelength.

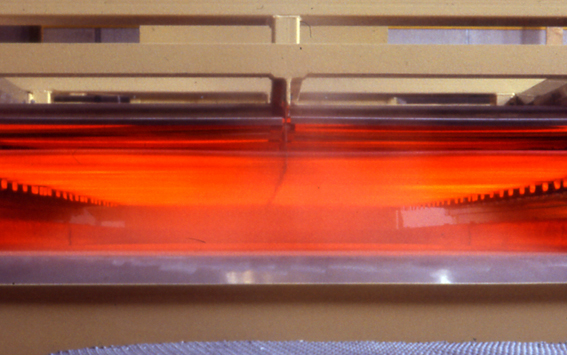

Travelling at the speed of light, infra red energy is extremely efficient at generating heat inside absorbent materials, by causing the constituent molecules to vibrate at a frequency of 80 – 170 million megacycles/second. The result, inter-molecular friction, brings about rapid internal heating and a rise in water vapour pressure.

Travelling at the speed of light, infra red energy is extremely efficient at generating heat inside absorbent materials, by causing the constituent molecules to vibrate at a frequency of 80 – 170 million megacycles/second. The result, inter-molecular friction, brings about rapid internal heating and a rise in water vapour pressure.

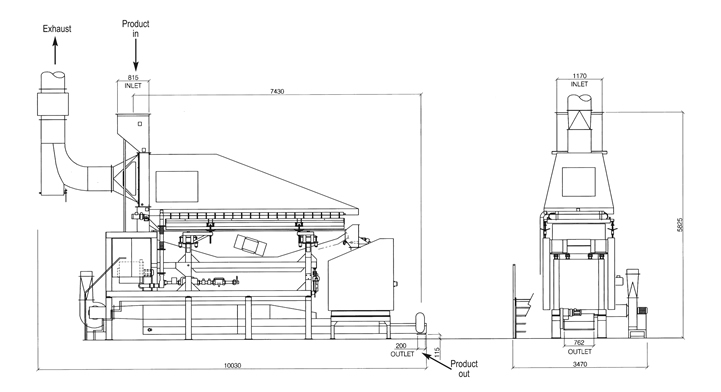

Infra Red Micronizing is a ‘short time, high temperature’ cooking process. Cereals, oil seeds, beans and pulses are all heated in a matter of seconds, without significant moisture loss. In cereal grains, for example, a surface temperature of 100ºC is achieved in 35 seconds.

As many university studies prove, digestibility is much improved – up to 98% for barley, while starch gelatinization in maize is as high as 90%. Energy is saved because drying is unnecessary. In addition the improvement in palatability, achieved by converting starches to sugars, enhances their flavour compared to other processes.

Wavelength and frequency of the specific part of the electro magnetic spectrum that concerns the Micronizing process can be viewed here.

Please see our contact page to request information on lecture papers

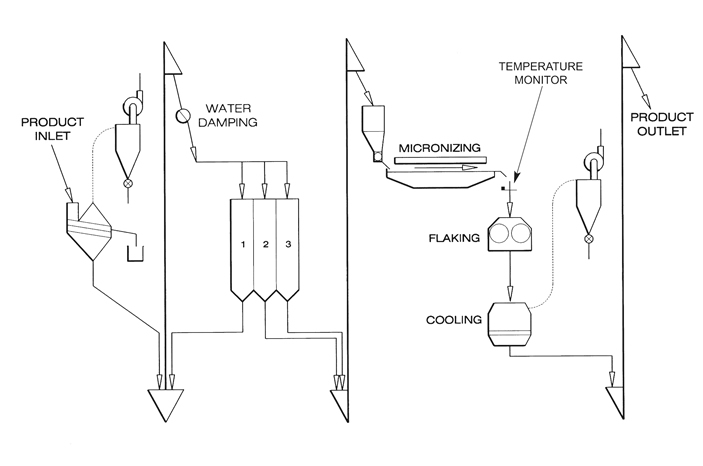

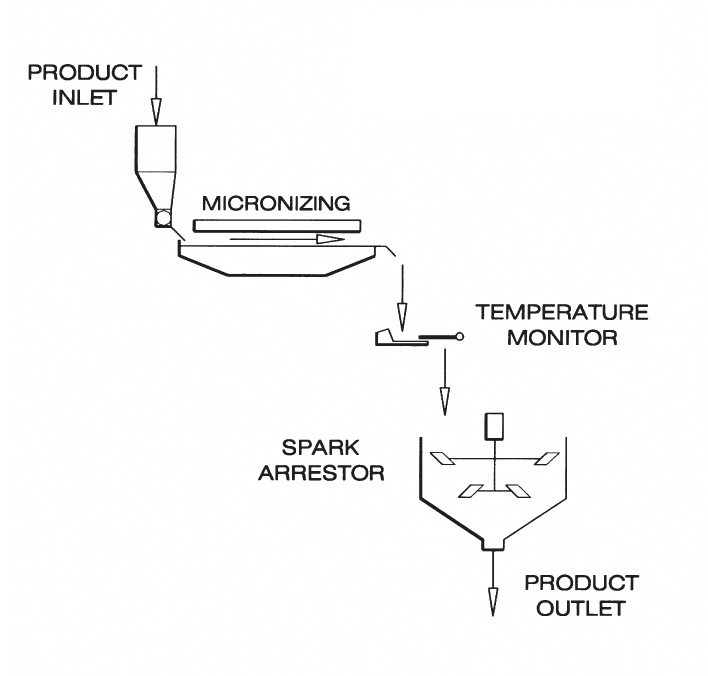

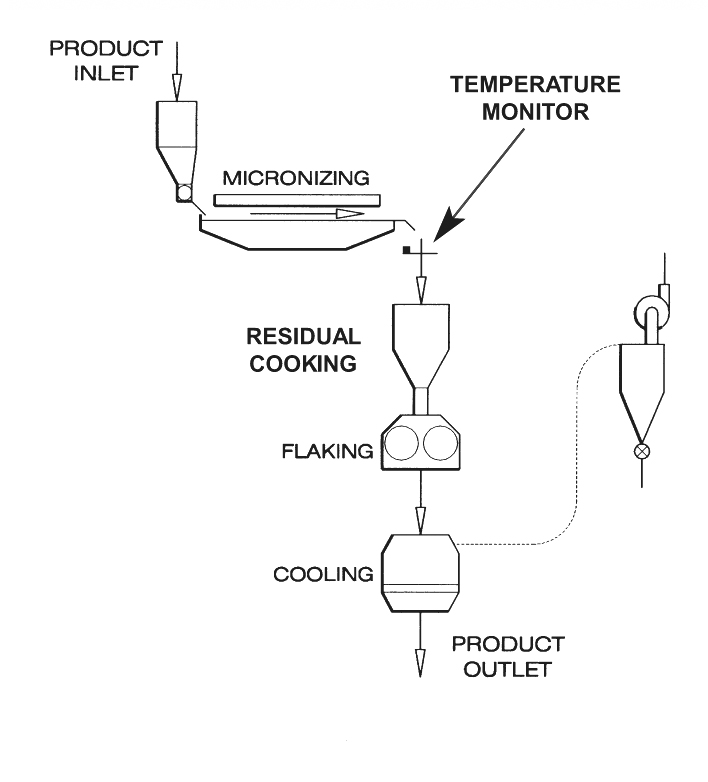

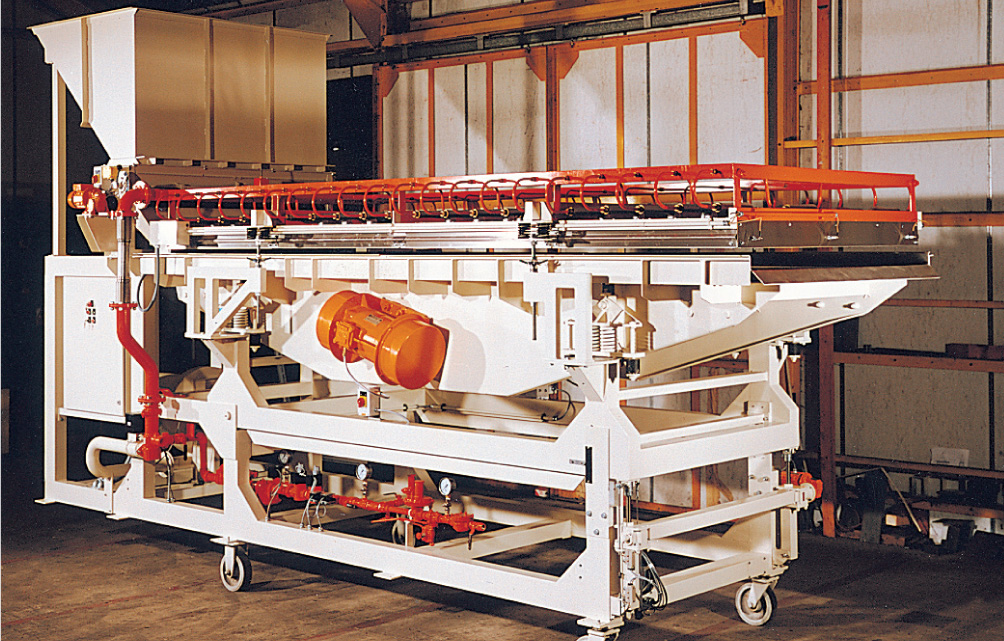

Flow diagrams for the cereal, cocoa, soya and animal feed micronizing process can be viewed here.